umshini wokufaka amalebula ohlangothini oluphindwe kabili imishini yelebula yesitsha esikhulu sepulasitiki

Umshini wokulebula we-adhesive kabili ozenzakalelayo onamathelayo ulungele ukusebenzisa amalebula ezitikha ohlangothini olungaphambili nangemuva lwamabhodlela, izimbiza, njll;eziyindilinga, eziyisicaba, ezimise okweqanda, eziwunxande noma eziyisikwele.Ijubane lokulebula liphinde lincike ekunyakazeni okuzinzile komkhiqizo kusihambisi semishini, ngesivinini esikhulu uma kuqhathaniswa.

| Amandla kagesi | I-AC110/220V 50/60HZ |

| Isivinini sokulebula | 20-60 amabhodlela/min |

| Ukunemba Kwelebula | ± 1mm (kuya ngokulingana kwendiza) |

| Iphrinta ukusebenzisa umoya | 5kg/cm2 |

| Roll Usayizi | Φ75 mm Φ200 mm |

| Usayizi welebula ofanelekile | 15-180mm (W)15-300mm (L) |

| Ubukhulu | 2000 mm(L)×1000mm(W)×1360mm(H) |

Isetshenziswa kakhulu kwezokwelapha, ukudla, isiphuzo nezinye izimboni entweni eyi-cylindrical noma into yebhodlela eliyisicaba lezidingo zokulebula okuzenzakalelayo.

1. Isebenza embonini yemithi, yokudla, yezimonyo nezinye, isiyingi sento eyindilinga nokunemba okuphezulu (izinga eliphindwe kabili) kanye nephuzu eligxilile nendawo kulebula elingemuva;Futhi ingahlangabezana nezidingo zokulebula zomkhiqizo we-taper.

2. Uhlelo oluthuthukisiwe lokusebenzisana nomshini womuntu, ukusebenza okulula, umsebenzi ophelele, lunomsebenzi wokusiza we-inthanethi ocebile.

3. Ibhodlela eliyingqayizivele endaweni enamaphuzu amathathu, gwema ukulebula emshinini wokulebula ibhodlela alivamile, futhi ibhodlela alibangelwa iphutha lokulebula okuqondile i-skew, bese livumela ukulebula okunembe kakhudlwana, okuhle, ukuphulula.

4. Ukutholwa kwe-photoelectric okuzenzakalelayo, kunomsebenzi wokuthi akukho lutho oluvela ku-conveyor futhi akukho ilebula ye-stick futhi ngaphandle kokulungiswa okuzenzakalelayo kwelebula noma umsebenzi wokutholwa okuzenzakalelayo kwe-alamu, ukuvimbela ukuvuza nokumosha.

5. Isakhiwo somshini silula, sihlangene, kulula ukusebenza nokugcinwa.

Ukucushwa kwezikhungo zamabhodlela amancane okuzenzakalelayo, ukuhlukaniswa okuzenzakalelayo ngaphambi kwesikhala samabhodlela, ukuqinisekisa ibhodlela lomhlahlandlela wokulandelela, ukulethwa kanye nokulebula kokuzinza;

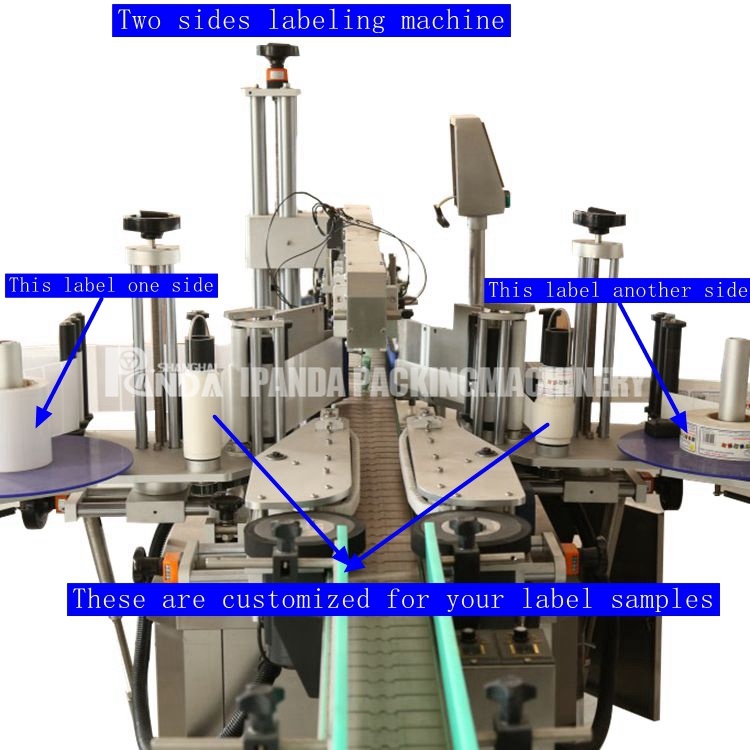

Indlela yokulebula ephindwe kabili iyalungiswa ukuze kuqinisekiswe ukunemba kokulebula kanye nokulebula kohlobo lwesibili lwe-extrusion okokuqala ngqa, iqeda ngempumelelo amabhamuza futhi iqinisekise ukuthi ilebula iqinile;