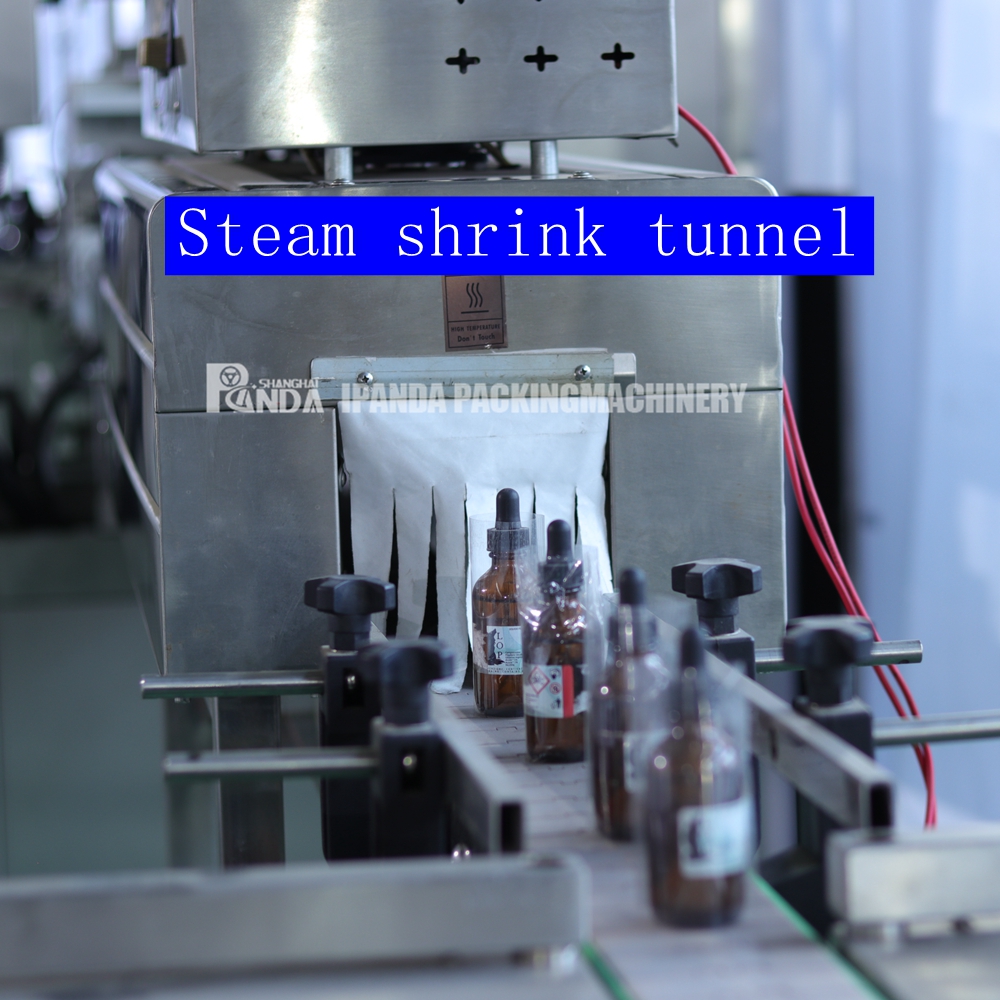

Ishampoo yokuwasha izitsha yeshawa umkhono webhodlela lebula yokushisa isitimu esishisayo sokuvalwa kokugoqa isifakeli se-shrink

Lo mshini usebenzisa ubuchwepheshe obuphambili bamazwe ngamazwe;vala ilebula lendilinga ebhodleleni lesilwane.Bese-ke kushisa kuncipha ukuze kulungiswe endaweni lapho umzimba webhodlela oqokwe khona.Isakhiwo salo mshini sihlangene, futhi sifanele umugqa wokukhiqiza wendlela ehlukene nobude obuhlukile.

Ingxenye yomshini isebenzisa ukwakheka okuhlanganisiwe kwe-modularization, futhi yenza umshini ube onengqondo.Ukulungiswa kobude kwamukela ukushintshashintsha kwemoto;kulula ukushintsha indaba.Ukuklama okukhethekile kwekhanda lokusika, kwenza ukusika kwefilimu-rolling ngokunembile nangokuthembekile.

| I-Dameter yamabhodlela afanelekile | 20-125 mm |

| Ukuphakama Kwebhodlela | 15-320 mm |

| Usayizi welebula (L*H) | 50-330-40-150 mm |

| Umumo webhodlela ofanelekile | nxazonke, isikwele, i-elliptical, unxande |

| Izinga lokulebula | ≥99.9% |

| Ubude Belebula | 25-200 mm |

| Lebula Ukuqina | 0.035-0.08mm |

| Lebula i-diameter yengqikithi yephepha | 3-10 mm |

| Amandla kagesi namandla | 220V, 2KW |

| Isisindo sengqikithi | 500KG |

1. Wonke umzimba oyinhloko wensimbi engagqwali evaliwe: Ukuphepha komsebenzisi.Wonke umshini awunawo amanzi futhi awugqwali.

2. Iphalethi lommese elilungisekayo: Ummese wohlobo oluyidizayini ehlukile, one-double blade ehlala isikhathi eside.

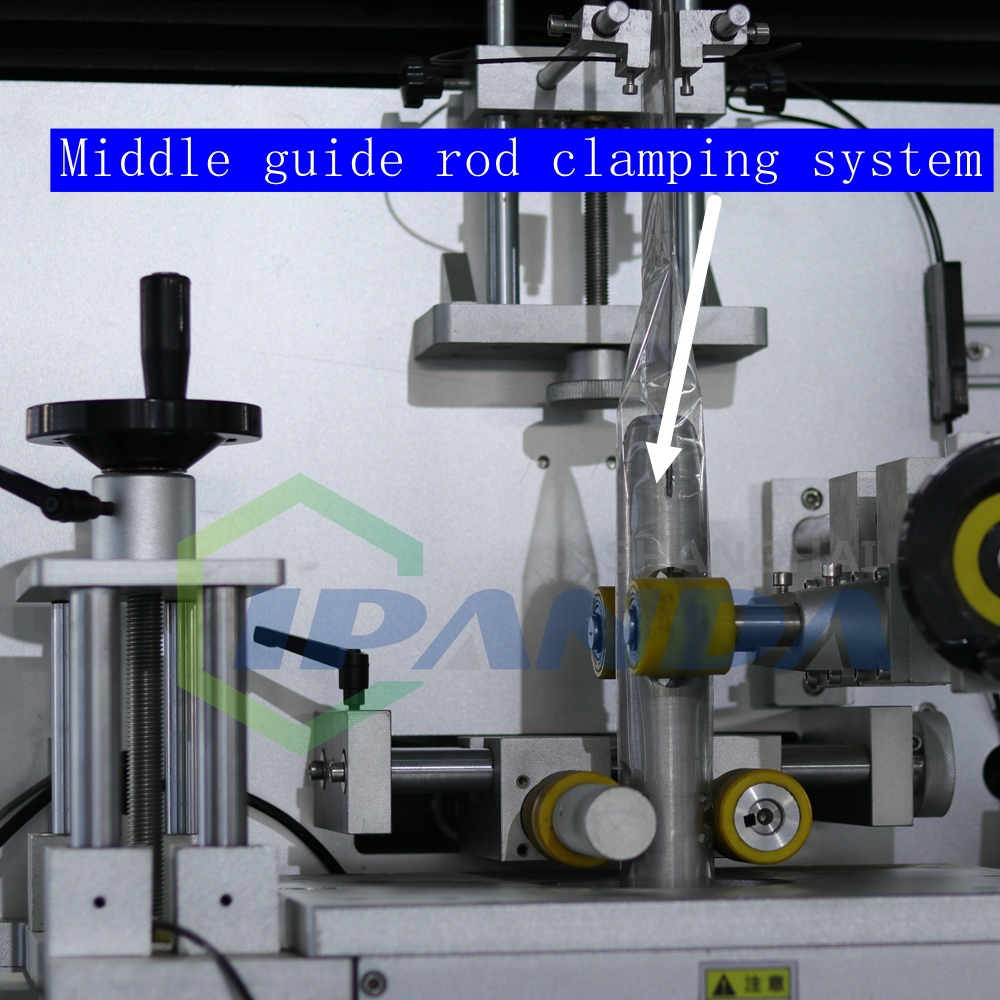

3. Ikholomu yokuma okukodwa: dlulisela ilebula ngokuzinzile

4. Ukulungiswa Kwesikhala Sebhodlela: ibhodlela ngeke liphelelwe isithuthuthu futhi linyakaze ngokuzinza

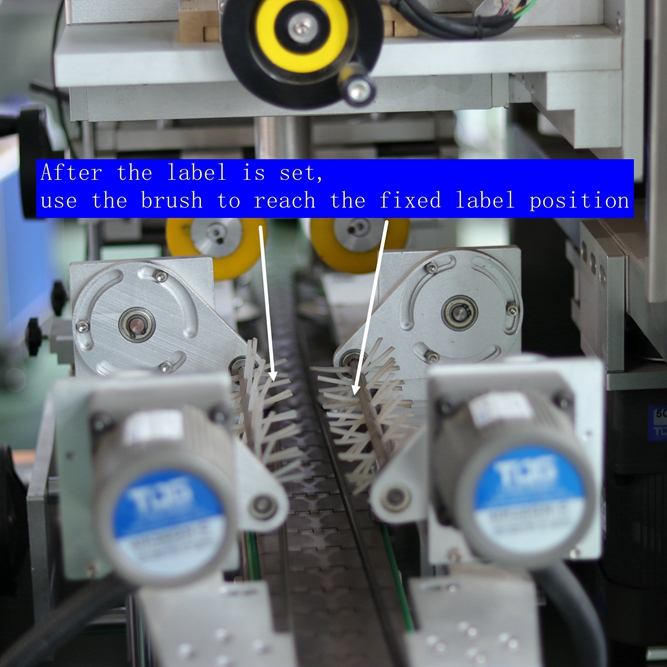

5. Ibhulashi ukuze uthole indawo yelebula: Inembe kakhudlwana.

6. Uhlaka lokulawula ilebula le-photocell: I-empennage eyingqayizivele ehlanganiswe ne-photocell, ithuthukisa ukunemba kokusika.

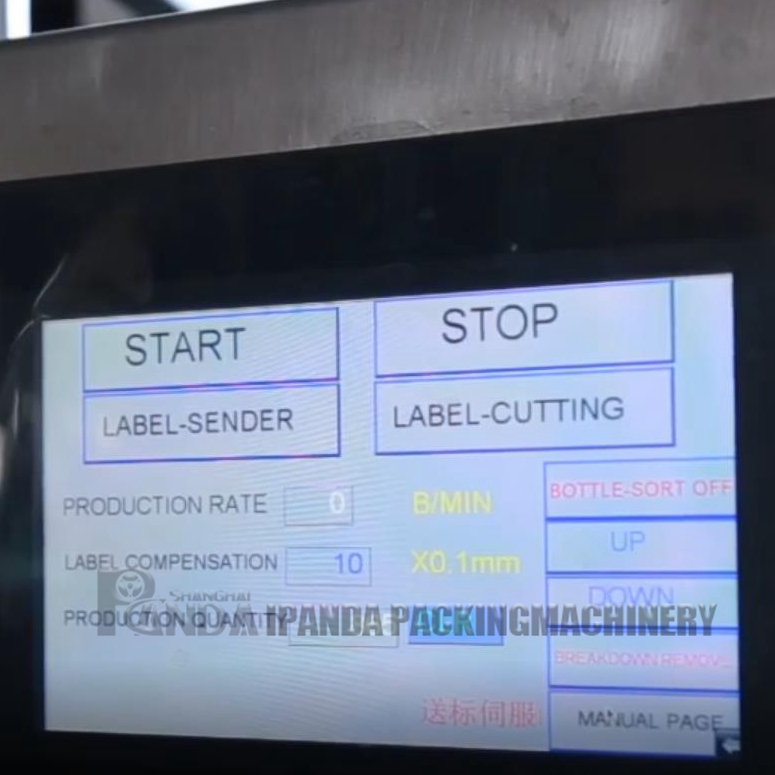

7. Isikrini se-HMI esinombala owodwa

8. Kulungiswe ngokuphakela Ibha yozimele

1. Wonke umugqa ungalungiswa ukukhiqizwa ngokuzenzakalelayo noma ngesandla: Ukulawulwa kwejubane okuzenzakalelayo: isimo esizenzakalelayo emshinini wethu singalungiswa ngokuya ngesivinini sokukhiqiza sangaphambilini ngokuzenzakalelayo, ngamabhodlela iso lomlingo, uhlelo lokulandela oluzenzakalelayo ngokugcwele olunomsebenzi olula futhi osheshayo Ukulawulwa kwe-automation Manual: kungaba ngokwezidingo zejubane lokukhiqiza ukulawula uhlelo lokulethwa, ukusebenza kwejubane lomuntu ngokugcwele.

2. Ukungasebenzi kahle komshini wonke kuthola ngokuzenzakalelayo, sebenzisana nesixhumi esibonakalayo somshini womuntu kusibonisi sesiShayina kanye ne-alamu yesibani se-trichromatic, thola ngesikhathi esifanele izizathu zokuhluleka kwemishini

3. Ukulethwa komshini kwesethi ephelele yezikhungo zokudlulisela okuvumelanayo zidinga ukulungisa i-knob, ungakwazi ukulungisa kalula isivinini sokugijima komshini.Umshini uthola ngokuzenzakalelayo ukulungisa isimo esizenzakalelayo.

4. Isikhungo sohlobo lwensika yomhlahlandlela wokuma okukodwa: izinze kakhudlwana ukuqondisa ilebula.

5. Ikhanda lokusika eliguquguqukayo: ukunqanyulwa kwe-cyclotron yasekuqaleni, i-double blade, impilo ende;

6. Uhlobo lwebhodlela olusebenzayo: isikwele esiyindilinga, isicaba, uhlobo lwenkomishi kanye namabhodlela ohlobo lwejika elingajwayelekile.

Isithombe semininingwane:

Ishalofu lamehlo kagesi elilawula ilebula:inhlanganisela eyingqayizivele yomsila kanye neso likagesi ukuthuthukisa ukunemba kokusika izinto zolwelwesi.

Ikhanda lokusika elilungisekayo:

i-cyclotron enqanyuliwe ngokungaqondile, unqenqema lokusika olunezinhlangothi ezimbili nempilo ende yenkonzo.

Insika yomhlahlandlela wesikhungo sokuposa esisodwa:okuzinze kakhudlwana ekulethweni kwelebula.